Salon Bio 360

Solution

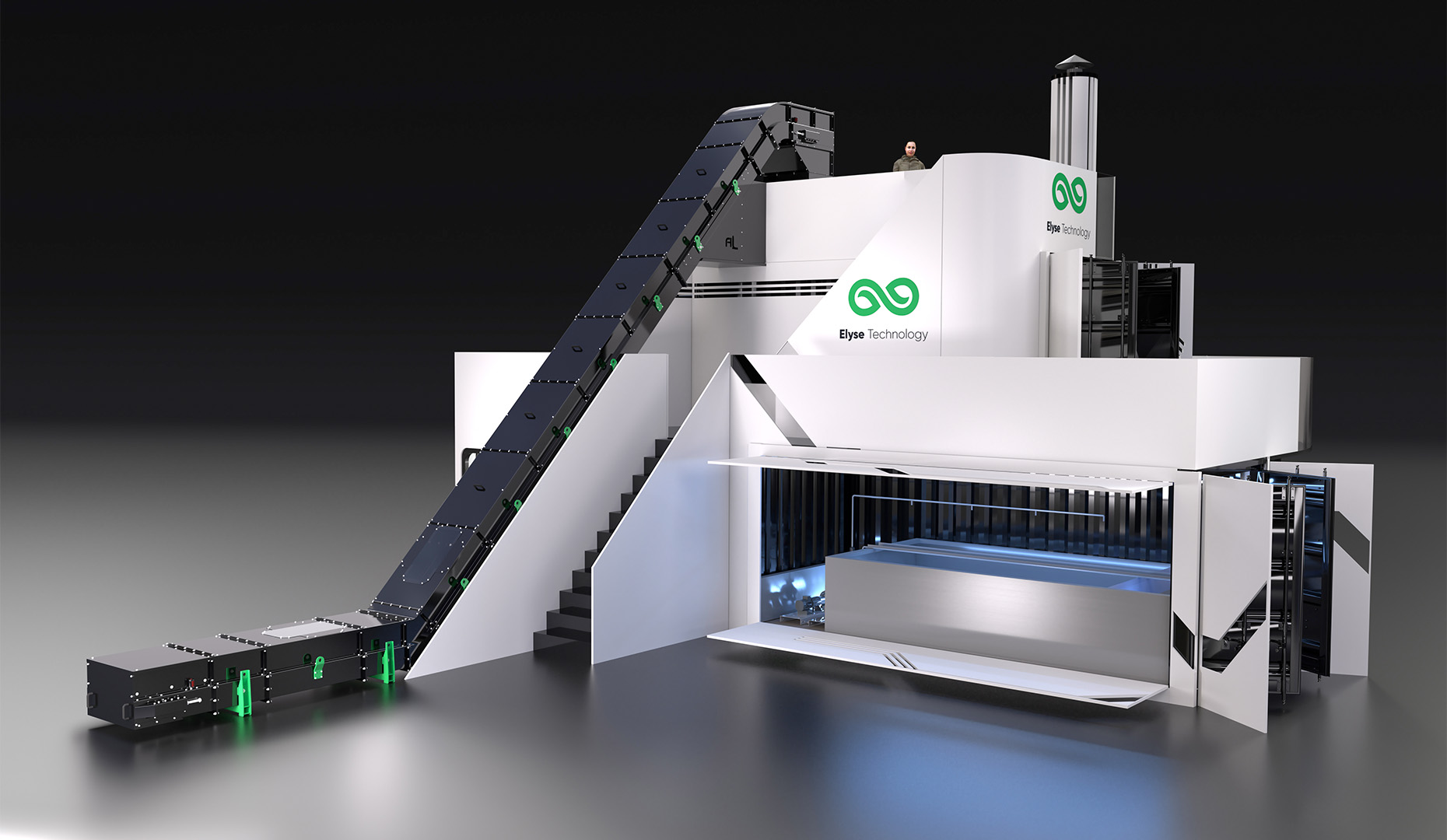

The Elyse Technology solution consists of recovering raw waste from industrial processes, biomass, into economically recoverable by-products: energy production (local or decentralized) independent of climatic/geopolitical conditions, reusable by-products in a manufacturing industry. process.

Compatible waste source

CARBOLYSE™ applies to any organic input. The first application of this process was the transformation of forest waste into petroleum products and charcoal.

The ELYSE TECHNOLOGY solution is based on a technical and economic approach. Although all organic waste can be recovered by the process, not all of it presents the same economic interest :

- Energy value of the waste,

- Quantity and quality of the waste deposit,

- Economic valorization of by-products (recycling, in-situ valorization, etc.),

- Etc.

We offer our solution to markets where the return on investment is the fastest. We endeavor to identify the existence of upstream and downstream valorization sectors to guarantee control of the value chain.

Modular and compact

Erection on site in one week as close as possible to waste deposit or process outlet.

The capacity is growing by adding production lines.

The transportable waste treatment solution offers the ability to move the unit to various waste sources, without additional investments.

Its compactness offer a better integration within regions, territories, cities.

Usable by-products

90% of your waste is converted into raw materials ready to be used or redistributed. The remaining 10% is directly used by the solution for its own operation. The production volume depends on the waste characteristics.

Gas

Syngas (synthesis gas) is obtained after separation of the condensable and non-condensable parts. It is mainly made up of carbon dioxide and monoxide, methane and hydrogen.

Its calorific value varies depending on the nature of the input. Part of it is used for the process, the rest is available depending on the uses (production of electricity, thermal energy, methanation, etc.).

This gas does not contain nitrogen (vacuum process).

Oil

Pyrolytic oil is obtained after separation of the condensable and non-condensable parts. Its composition and calorific value vary depending on the nature of the input. The separation method can help obtain easily recoverable “cuts”.

These oils can be reused depending on the case, as a substitute for fossil energy, a precursor in processing industries, etc.

Solid

At the end of the process, all that remains is the solid material transformed into a carbon compound close to the consistency of “charcoal”.

Its mechanical characteristics and calorific value depend on the nature of the input.

These compounds can be reused in agriculture (fertilizers), precursor in the processing industries (rubber), the road industry, specific applications (filtration system).

Low carbon energy production

Elyse Technology joins forces with partners to offer technological bricks adapted to its customers' business plans :

- From electricity production to syngas recovery for reinjection into the network

- Additional technologies for the most neutral carbon footprint.

Biogas

Biofuel

Electricity production

Agriculture

Algoculture

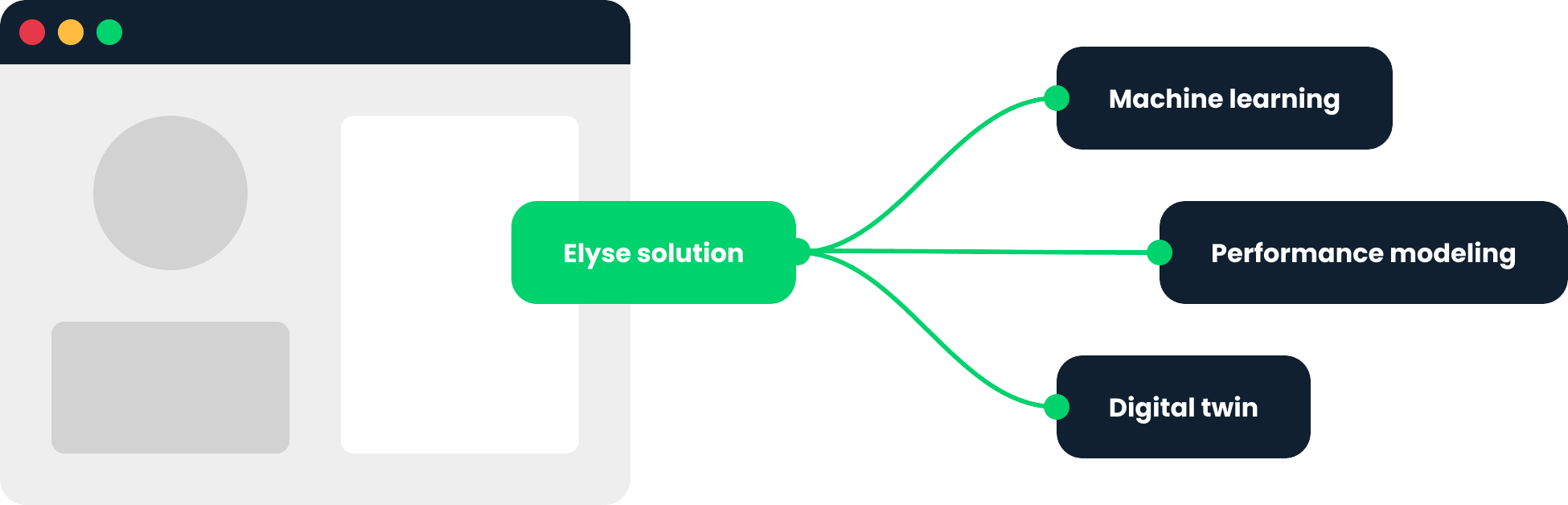

CPM Software

Inside Elyse, innovation never stops. CPM Software offers a suite of software solutions for testing new inputs in a virtual factory, a decision-making tool to “optimize” the management of an installation.